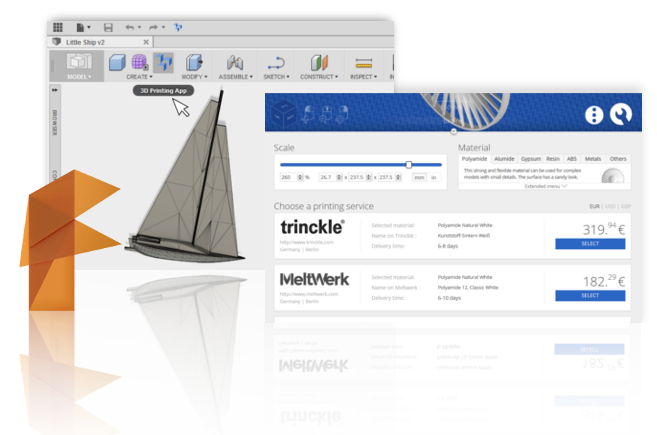

Putting the parts together in the end is made simple due to automatic part labelling, but nothing makes it easier than the animations Slicer produces. When you select that winning design, you can create DXF’s to use as true scale stencils for manual operations, or you can take them to Fusion 360 to create toolpaths for your laser or waterjet. Built in are DYNAMIC checks to ensure that parts are connected and that interferences are avoided as demonstrated by the red pieces in the gif below: With Slicer for Fusion 360, you can explore different construction techniques to capture design intent, limit material use, or explore stock selection and finish. From there, to take your models from Fusion to Slicer, all you’ll need to do is hit the 3D Print button… Once that’s done, you can then add it as a “custom” selection from within the 3D print command. First, you’ll need to get and install it from the App Store. Step 1 is to get this tool to work seamlessly with Fusion 360. These, when teamed with Slicer for Fusion 360, will allow you to make incredible and complex designs. Built upon the 123D Make technology, this tool enables you to produce 3D products by slicing the models in a plethora of ways.

More likely, you’ll find a bandsaw, jigsaw, or even a hand saw. I’d also guess that most of you don’t have a CNC in your garage…except for Curt of course.

I’d venture to guess that all of you know that design is just small part of producing real products.

0 kommentar(er)

0 kommentar(er)